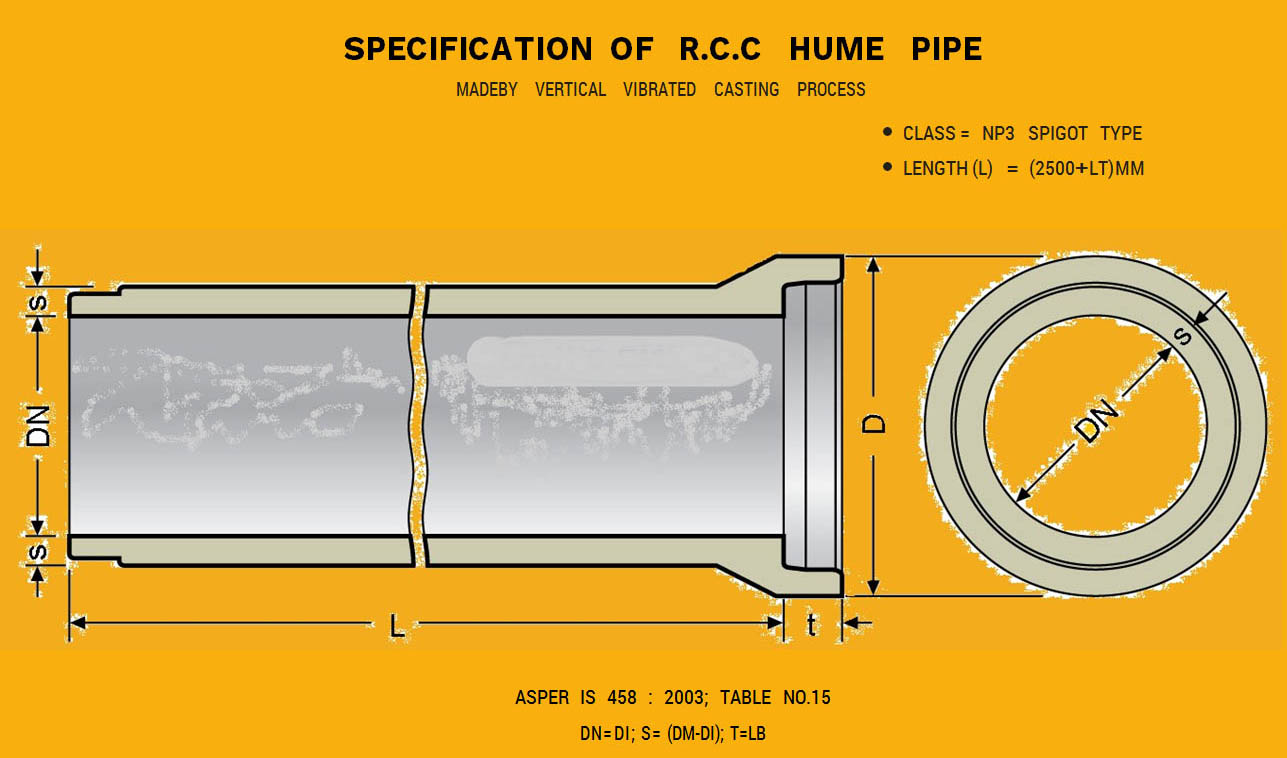

(AS PER IS 458 : 2003)

| ID (MM) | Weight (Kg.) |

|---|---|

| 600 | 21.7 |

| 700 | 30.34 |

GRADE OF CONCRETE : M35

SLUMP = (0 - 10) MM

WATER CEMENT RATIO = 0.23

TYPE OF CEMENT = OPC - 53GRADE

LONGITUDINAL BAR = 8 MM HDS SPIRAL = 5 MM / 8 MM HDS

| INNER DIA | Weight of Cage |

|---|---|

| 800 MM | 25.16 KG |

| 900 MM | 37.52 KG |

| 1000 MM | 48.5 KG |

| 1200 MM | 65.5 KG |

| 1400 MM | 88.6 KG |

| 1600 MM | 143.1 KG |

| 1800 MM | 192.2 KG |

| 2000 MM | 252.5 KG |

A JACKING PIPE IS A HIGH COMPRESSIVE STRENGTH PIPE THAT IS JACKED INTO THE EARTH USING THE PIPE JACKING TECHNIQUE . THE PIPES ARE JACKED THROUGH THE SOIL BY USING HYDRAULIC JACKS THAT DRIVE THE SHIELD AT THE FRONT OF THE PIPE STRING . PIPE JACKING IS A TRENCHLESS CONSTRUCTION METHOD THAT IS CARRIED OUT FROM A LAUNCHP IT POSITIONED AT THE DEPTH AT WHICH THE PIPE IS TO BE INSTALLED . THE METHOD IS VERY USEFUL WHEN PIPELINE INSTALLATION HAS TO BE CARRIED OUT IN PLACES WHERE SURFACE DISRUPTION IS TO BE MINIMIZED SUCH AS UNDER ROADWAYS , HIGHWAYS , RUNWAYS AND RAILWAYS .

MICROTUNNELING AND PIPE JACKING ARE TWO OF THE METHODS OFTRENCHLESS CONSTRUCTION THAT UTILIZE JACKING PIPES . THE PROCESS INVOLVES DIGGING A LAUNCH SHAFT FOR PLACING THE REQUIRED MACHINERY AND EQUIPMENT THAT WILL DRIVE THE PIPEINSIDE THE SOIL . ALSO KNOWN AS THRUST PIT , A THRUST WALL ISINSTALLED AT THE BACK OF THE PIT TO GAIN THE REQUIRED THRUST FOR THE JACK TO PUSH THE PIPE POSITIONED BEHIND ASHIELD . AS THE DIGGING PROCEEDS THE PIPES ARE PUSHED IN BEHINDAS A STRING . THE INSTALLED PIPE IS WATERTIGHT AND STRUCTURALLY SOUND WITH FLEXIBLE GASKETED JOINTS . THE RECEIVING SHAFT AT THE OTHER END ALLOWS THE SHIELD TO BERETRIEVED AT THE OTHER END AS IT THE PIPELINE LENGTH IS COMPLETED .